This machineвҖҷs fore and back beams adopt high steel box construction. The right of beams is round rail. The two sidesвҖҷ rail of beams and round вҖ“end rail all inlaying quenched hard steel guide, more than ten times as the use period of normal one. The machine uses chainless ball bearing transmission, turning sliding touch into rolling touch of the bearing and rail, reducing pulling force and making transmission steadily. The different frequency-changing speed of main transmission is decreased by gear and worm gear, bigger range of adjusting speed, easy to operate and reliable. This machine adopts PLC control, Touch Screen display processed thickness, working speed and processed meters, reliable control, adjust conveniently. In addition, it has good protection system, reasonable lubricating system and perfect appearance.

It is applicable to process 3пҪһ50mm glass straight-line. Rough/fine grinding and polishing can be finished in one single passage. The surface of processed glass can reach the degree of normal mirror, and has high precision straight line. It can meet high precision and highly polished requirementsвҖҷ glass straight-line edging processing.

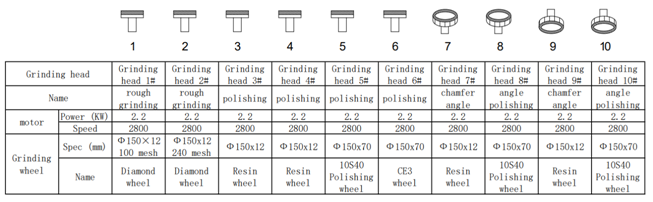

Wheels placement

| Main technical dataпјҡ |

| Max.Glass size | 2500Г—3600mm |

| Min.Glass size | 30Г—30mm |

| Glass thickness | 3-50mm |

| Transmission speed | 0.5-7m/min |

| Max.hemline grinding | 5mm |

| Arris grinding range | 0.5-5mm |

| Power | 25KW |

| Weight | 5500kg |

| Land occupation | 7200Г—1000Г—2500mm |

| glass diagonal error | вүӨ0.5mm/m |

| glass parallelism error | вүӨ0.3mm/m |

| Details with photos |

Heavy basement about 1600KGS, 360mm thickness, keeps the machine more stable while processing the heavy and overload size glass. Heavy basement about 1600KGS, 360mm thickness, keeps the machine more stable while processing the heavy and overload size glass. |

The guide bar is made of 40Cr steel, with high hardness, good wear resistance and long service life. The thickness of the support seat of the guide bar reaches 25mm for the support strength is higher and more stable. The front and rear beam are made of 35mm steel plate with two annealing treatments eliminate internal stress, ensure no deformation, and better overall stability. The guide bar is made of 40Cr steel, with high hardness, good wear resistance and long service life. The thickness of the support seat of the guide bar reaches 25mm for the support strength is higher and more stable. The front and rear beam are made of 35mm steel plate with two annealing treatments eliminate internal stress, ensure no deformation, and better overall stability. |

Adopt two big 110 RV Gear reducer to make the machine run more stable with bigger power, and durable. Adopt two big 110 RV Gear reducer to make the machine run more stable with bigger power, and durable. |

Adopt the frequency inverter motor and Hard-tooth reducer to ensure keeps the machine more stable while processing the heavy and overload size glass. The motor is 410mm length, 260mm width. Adopt the frequency inverter motor and Hard-tooth reducer to ensure keeps the machine more stable while processing the heavy and overload size glass. The motor is 410mm length, 260mm width. |

All Spindle use Original ABB motor, durable and reliable for use. All motor is the same type 2.2KW, itвҖҷs better for future service and the customer prestored the motor. All Spindle use Original ABB motor, durable and reliable for use. All motor is the same type 2.2KW, itвҖҷs better for future service and the customer prestored the motor. |

Adopt special bearing base and install taper adjusting bearing, it will be more durable and reliable for use. High transmission accuracy. Adopt special bearing base and install taper adjusting bearing, it will be more durable and reliable for use. High transmission accuracy. |

The link shaft and the link buckle are made of 40 CR material, with strong rigidity and no deformation. The cross positioning of guide bearing and load bearing to ensures high accuracy and stable transmission. And the link shaft is processed with the guide oil groove to make the lubrication in place. The link shaft and the link buckle are made of 40 CR material, with strong rigidity and no deformation. The cross positioning of guide bearing and load bearing to ensures high accuracy and stable transmission. And the link shaft is processed with the guide oil groove to make the lubrication in place. |

Better lubricating system, there is two big oil tanks onto the front&back beam, it will stock the oil and distribute the oil to the bearing of pads with the pipe, the oil pipe would be touch to the bearing ensure lubricate to each bearing, which have long service life and durable. Better lubricating system, there is two big oil tanks onto the front&back beam, it will stock the oil and distribute the oil to the bearing of pads with the pipe, the oil pipe would be touch to the bearing ensure lubricate to each bearing, which have long service life and durable. |

Adopt the Schneider electric with neat line layout which make the machine more safety and running smoothly.

|

Adopt SIEMENS PLC and SIEMENS touch screen to show glass thickness, speed and more information which is easy for operation.

|

Adopt the high-quality timing belt with 2PU to convey the glass, which has longer service life and more accurate. Adopt the high-quality timing belt with 2PU to convey the glass, which has longer service life and more accurate. |

It has the safety system in the entry&exit end, when the hand touches this steel plate, it will automatically close and then the machine will be stop running, we call this is Anti-hand clamping device. It has the safety system in the entry&exit end, when the hand touches this steel plate, it will automatically close and then the machine will be stop running, we call this is Anti-hand clamping device. |

vertical adjustment and LED display for glass removal system, for this reason it is not necessary to adjust the position of wheels, acting instead on the handwheel placed beneath the conveyor. vertical adjustment and LED display for glass removal system, for this reason it is not necessary to adjust the position of wheels, acting instead on the handwheel placed beneath the conveyor. |

loading/unloading table, on top of the gearbox at the exit, so that the water wonвҖҷt be directly to the floor and to the machine. |

Adopt perfect waterproof system with 02 layers brushes onto the water tank. Adopt perfect waterproof system with 02 layers brushes onto the water tank. |

Adopt perfect Interactive waterproof system with 03 layers brushes to protect the bearing far from water and not moisture, easy to disassemble and replace. Adopt perfect Interactive waterproof system with 03 layers brushes to protect the bearing far from water and not moisture, easy to disassemble and replace. |

Adopt of quality stainless steel water tank which is corrosion resistant and more durable. Adopt of quality stainless steel water tank which is corrosion resistant and more durable. |

With PVC drainage pipe, which has long life, smooth drainage, easy maintenance and better looking. With PVC drainage pipe, which has long life, smooth drainage, easy maintenance and better looking. |

Mini-washer is equipped on the front & back beam to keep the tracks (rubber pads) clean to avoid incrustations and facilitate glass cleaning at the end of processing. |

In order to facilitate the maintenance of the track sliding guide, an automatic centralized lubricating device fitted. Timely lubricating. In order to facilitate the maintenance of the track sliding guide, an automatic centralized lubricating device fitted. Timely lubricating. |

The configuration brand of Major parts and the feature

(Some configuration brands may be replaced due to products improvement without notify and Debo will have the right of final explanation.)

| Electric Parts: |

| NO. | name | Supplier |

1

| AC contactor | Schneider Electric |

| 2 | Overload relay | Schneider Electric |

| 3 | Transformer | Schneider Electric |

| 4 | Circuit breaker | Schneider Electric |

| 5 | Ammeter/Voltmeter | AOYI electric |

| 6 | Button/light | Shanghai Electric |

| 7 | Spindle motor | ABB |

| 8 | PLC | SIMENSE |

| 9 | Touch screen | SIMENSE |

| 10 | Encoder | OMRON |